Mark your bend lines.

How to form a multi curved sheet metal.

Sheet metal depends on certain parameters 1 thickness 2 bend radius 3 bend angle.

A sheet metal disc is rotated at high speeds while rollers press the sheet against a tool called a mandrel to form the shape of the desired part.

L ᴫ 2 r y t θ 90.

Spinning sometimes called spin forming is a metal forming process used to form cylindrical parts by rotating a piece of sheet metal while forces are applied to one side.

1 introduction sheet metal introduction 2 primary walls and secondary walls 3 sheetmetal parameters 4 k factor and y factor 5 various sheet metal tools 6 creating sheet metal components.

How to bend sheet metal without a brake.

Now that you know your bend allowance take your protractor and draw a clear line with your marker across the point at which you will bend your sheet metal.

Stroking the metal through the wheels at different angles makes it possible to form almost any curved or dished shape.

I took what i knew of the sheet metal and applied it to a standard 3d model to see if i could convert and flat pattern.

It takes considerable practice to know where with which wheel combinations with what pressures and for how many strokes to use an english wheel.

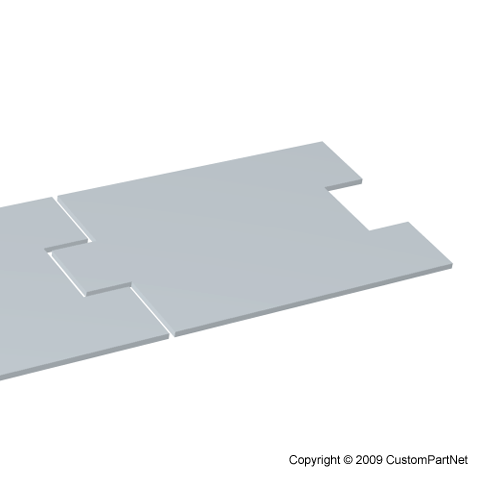

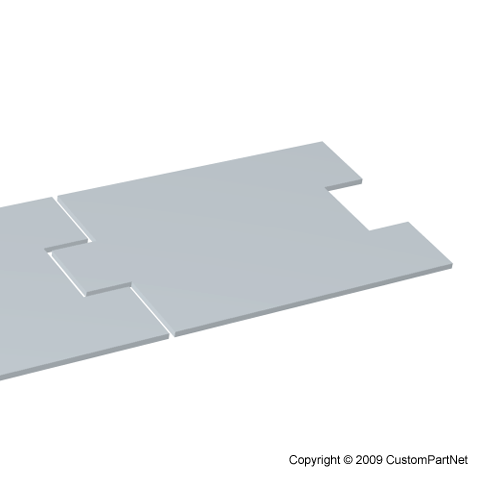

Sheet metal multiple bends opposite directions attached is an image of what i am trying to accomplish.

How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools.

How can you go about shaping metal with hand tools alone.