Aluminum sheet weight calculation material alloy steel aluminum beryllium brass bronze cast iron columbium copper copper alloys gold lead magnesium molybdenum nickel plastic silver stainless steel tantalum titanium tungsten zinc zirconium.

How to figure the cost of aluminum sheet.

Ultimate tensile strength psi.

Common alloy perforated aluminum sheet.

The metal weight calculator allows you to calculate the weight in pounds for your steel stainless steel aluminum iron silver and much more.

Aluminum roof pricing and installation cost checklist.

Punch edge radius in.

The cost of the raw material per one piece is given by this formula.

Labor costs associated with running the machine including the time to handle raw material finished parts and remnants and attending the machinery while it s running when required.

To place a value on these costs you must know the hourly cost of an operator the amount of time it takes.

Metal gets heavy and whether you want to see how much shipping is likely to be or if your vehicle or back can handle it it s good to know what your order weighs.

Expect the aluminum roof prices to fluctuate between various companies each and every company have different operation expenses and over head.

To help with that we ve got our handy weight calculator here.

192 3 0 90 material utilization with reclaim 2 mils thickness 1 4 specific gravity ft.

2 at a thickness of 1 mil.

If you need 300 sheets of metal for example and each sheet.

How to calculate sheet cost by cwt.

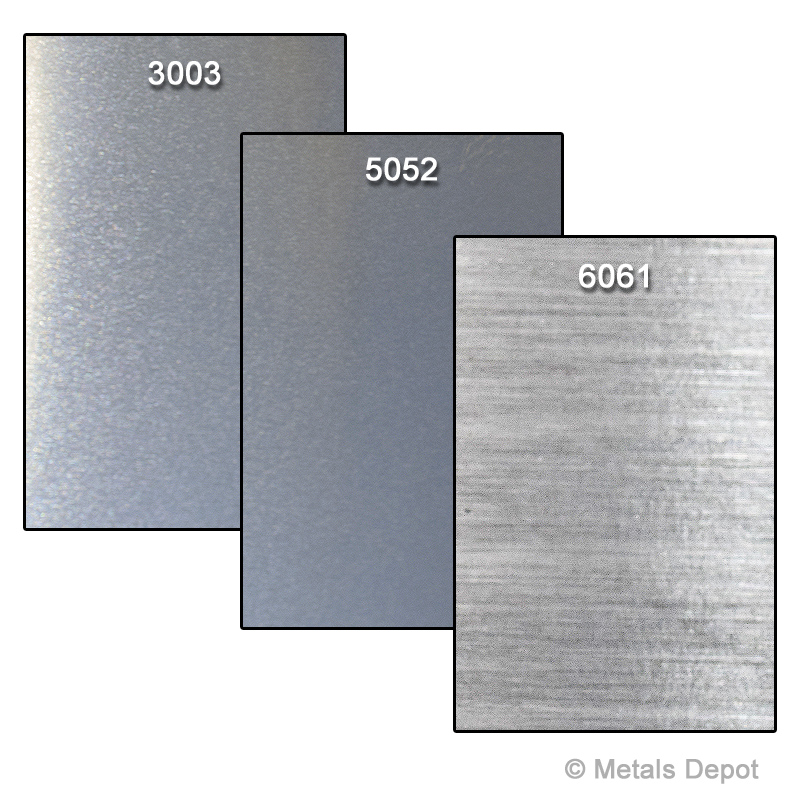

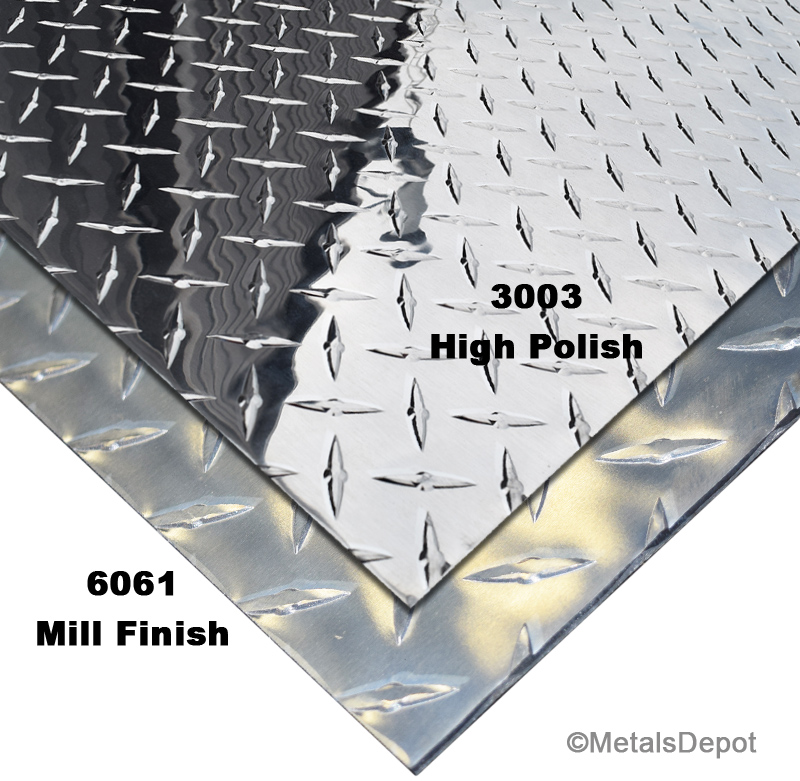

3003 5052 6061 cast tooling aluminum sheet plate.

Find the total weight of all the sheet based products you want to buy.

Common alloy expanded aluminum sheet.

That is the starting point for calculating the powder cost.

Get at least 3 5 estimates before hiring a aluminum roof contractor estimates are typically free unless it s a service call for a repair.

A pound of powder with a specific gravity of 1 0 at 100 percent utilization will cover 192 3 ft.

In this case i prefer to see it as a part of the investment to complete the production of n parts and use this formula.

173 2 8 61 8 ft.

To compare the economics of these machines costs were divided into three categories.

Die edge radius in.

Divide the total number of pounds by 100 to find the cwt or hundredweight of the sheets you need to buy.